Areas

Areas

Mobility, Development and Application of Composite Materials.

Thermosets

We specialize in the development of advanced solutions for industry, with a particular focus on the aeronautical sector.

Thermoplastics

In this area, we primarily work on developing solutions for industry, primarily aeronautical, using thermoplastic composite materials.

NextGen

Fidamc's NextGen division is dedicated to innovation and development in three key areas: robotics, industrial digitalization, and advanced materials.

Engineering

Fidamc's Engineering team is at the heart of innovation and technological development within the organization.

Laboratory, NDT, and QEMS Group

The Laboratory, NDT, and QEMS Group team is part of Fidamc's scientific and technical department and plays a crucial role in the research, development, and validation of advanced materials and processes.

Production

Fidamc's production team is essential to the implementation and execution of our composite materials and advanced technology development projects.

Lastest news

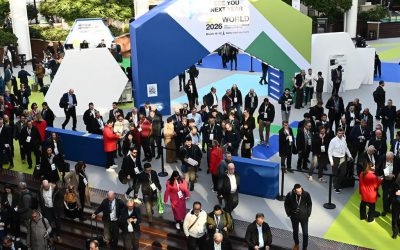

Fidamc will participate in several trade fairs in the first quarter of 2026

En Fidamc estamos muy ilusionados por confirmar nuestra participación en tres de las ferias más relevantes del sector tecnológico e industrial de los próximos meses. Estos...

The inauguration of the CFA and the Aerospace Thermoplastics International Summit, Fidamc's milestones for 2025

El año 2025 ha sido un ejercicio de gran dinamismo para Fidamc, marcado por hitos clave tanto en España como en escenarios internacionales, un fortalecimiento de alianzas...

Airborne and Fidamc announce Strategic Partnership to advance Composite Manufacturing Automation

Airborne, líder en automatización y digitalización de procesos de fabricación de compuestos, y FIDAMC anunciaron un memorando de entendimiento (MOU) para establecer una...

Projects

At Fidamc we have years of experience in the aeronautical sector, which allows us to transfer the vast knowledge acquired to other industrial sectors, where weight reduction and environmental protection are key priorities.

We have the capacity to develop test plans to validate structural and functional concepts, covering all stages of the innovation process, from the initial phases to the most advanced and closest to industrial application.We develop all the necessary elements for the complete execution of the tests, including physical-chemical and mechanical characterisation tests of materials, the definition of manufacturing processes and tooling, as well as the necessary equipment to process the materials and the quality verification tools.

We develop highly innovative processes that respond to current market needs, reduce manufacturing costs and increase production rates. These innovations are applied to various technologies, such as thermoset prepreg, resin transfer processes (infusion and injection techniques for thermosets), thermoplastics, advanced high-speed manufacturing processes (Industry 4.0 and digitalisation), process analysis and simulation, and additive manufacturing.

Thermosets Prepreg

We have exceptional facilities with the necessary industrial equipment and state-of-the-art equipment. We have automatic taping equipment for the manufacture of large-scale demonstrators in both ATL (Automated Tape Lay-up) and AFP (Automated Fibre Placement) processes and for dry or pre-impregnated material. We also have equipment for membrane or press forming, forming and curing in an autoclave oven or press. Finally, and when the project requires it, we manufacture special devices.

We specialise in:

- Developments of high structural integration of components, both for torsional box structures of airframes, fuselages and space launchers, whose structural concepts and processes are validated by means of full-scale demonstrators.

- Analysis of the architecture of laminates to optimise their structural behaviour and manufacturability.

We also incorporate our own technologies in the development of materials that do not require autoclave curing (AoA). This is the case of the DVD project for components previously certified with autoclave curing, where a clear reduction in manufacturing costs is achieved while maintaining the same mechanical properties.

Link to Thermoset Prepreg Projects

Dry fiber and resin transfer processing

Automatic dry fibre taping.

We manufacture aeronautical stiffened structures through infusion processes and manufacture complex geometry components by RTM (Resin Transfer Molding) such as window frames, frames, beams and other highly integrated elements.

Automatic Fiber Placement AFP (Automatic Fiber Placement) taping of fuselage panels and airframe surfaces.

Optimisation of manufacturing conditions to ensure component formability (by press or membrane) and infusibility.

Thermoplastics

We currently have a machine that allows the thermoplastic material to be consolidated during the taping process itself (‘in-situ’ consolidation process). In-situ’ consolidation makes it possible to dispense with the autoclave or oven and the integration of the stiffening elements is also carried out, which saves costs in the component manufacturing process.

This development has been carried out in collaboration with MTorres and Airbus DS, within the framework of different projects financed through the CDTI and the European Union.

There is also extensive know-how in the manufacture of thermoplastic components for the aeronautical sector by means of press forming or stove-forming processes.

These capabilities extend, as in the rest of the cases, to the characterisation of the material from the physical-chemical and mechanical point of view and to the performance of the appropriate quality inspections of the manufactured component.

Much of the knowledge is available in specific training courses.

Link to Thermoplastic Projects

Analysis and simulation of processes

FIDAMC has a highly experienced team in structural design and optimisation. Its capabilities include structural analysis, design optimisation (CATIA), analysis of finite element models (ABAQUS and NASTRAN) and fracture mechanics studies, a field in which it is developing several doctoral theses and participating in projects financed by the European Union.

From the point of view of manufacturing processes, the simulation of: Filling times, resin distribution and flow in infusion and injection processes, prediction of fibre distortion in forming processes (press and membrane), forming capabilities of complex parts, determination of spring-back during the curing process or estimation of residual stresses during the manufacturing process. It also has the ability to define and carry out material characterisation tests to feed the simulation processes.

Trustees

Certifications

EN9001 Sistemas de Gestión de la Calidad

EN 9100 Sistema de Gestión Aeroespacial

ISO14001 Sistema de Gestión Ambiental

ISO14001 Environmental Management System

ISO17025 Requisitos generales de la competencia de los laboratorios de ensayo y calibración

NADCAP. Non Metallic Materials Testing

Airbus Qualified Special Process List

Airbus Qualified Test Method List

Commitment to the environment

Continuing with our commitment to the environment. One of our main areas of action is energy efficiency. We strive to reduce our energy consumption and minimise our carbon footprint.

List of completed projects

Projects covered by the incentive scheme under the Recovery, Transformation and Resilience Plan, funded by the European Union – NextGeneration EU.

Avenida Rita Levi Montalcini, 29 (28906 Getafe - Madrid). Installation of a rooftop photovoltaic system for self-consumption using renewable energy with a power output of 350.17 kWp.