In recent years, so-called quantum technologies have ceased to be a futuristic concept and have become a strategic field with real applications in industry, defence and space. Beyond quantum computing, quantum technologies are revolutionising the way we design, monitor and optimise advanced materials.

In this context, quantum technology not only provides new devices, but also new capabilities to integrate intelligence into materials, improve manufacturing processes and move towards increasingly efficient, safe and multifunctional structures. Below, we analyse how these technologies can be applied in the field of composite materials and smart structures.

Sensors and quantum metrology for smart structures

One of the major challenges in the development of smart structures is the real-time monitoring of their properties and structural health. Being able to measure parameters such as temperature, pressure, stress or deformation from within the material would save millions in maintenance costs and downtime for inspections.

However, this requires extremely miniaturised, lightweight sensors with minimal interference, capable of being integrated into the composite material itself without compromising its performance.

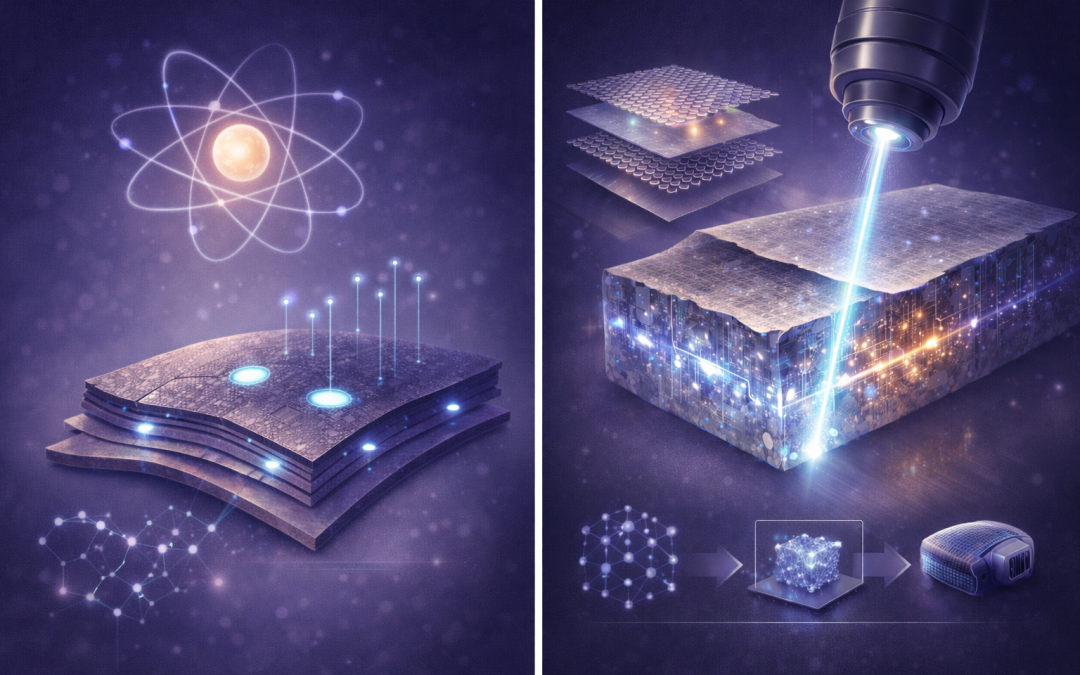

This is where quantum materials and sensors offer a differential advantage. Technologies based on spin defects in hexagonal boron nitride (hBN) and other 2D materials, as well as nitrogen-vacancy (NV) centres in diamond, enable the development of highly sensitive sensors with nanometric dimensions. These devices can provide accurate and continuous information, facilitating a new generation of self-monitoring structures.

Quantum materials and multifunctionality

Another current challenge in materials engineering is the incorporation of new functionalities into structural composites. The trend is towards materials capable of modifying their electronic, magnetic, thermal or optical properties depending on the environment: truly intelligent structures.

To achieve this, it is necessary to design and implement increasingly smaller and more efficient multifunctional particles.

In this field, 2D materials—such as graphene and other Van der Waals materials—have already demonstrated their ability to functionalise composites, modifying their electromagnetic, optical and mechanical properties. These integrations open the door to new applications in signal control, thermal dissipation and structural reinforcement.

More recently, technologies such as quantum dots have begun to be used to precisely adjust the interaction of coatings with light. This enables strategic applications in low observability, as well as in the thermal regulation of space systems, where radiative control is key.

Multiscale simulation: from atom to component

In order to incorporate new functionalities and design materials down to the nanoscale, it is essential to understand their behaviour at the atomic level. This is one of the greatest challenges today: connecting what happens at the quantum scale with the macroscopic performance of the final component.

It is important not to confuse this approach with physical quantum simulators; here we are talking about computational simulation of materials.

Multiscale simulations allow us to model macroscopic behaviour with great precision based on its fundamental properties. To do this, quantum material simulation techniques—such as Tight-Binding or Density Functional Theory (DFT)—are combined with classical materials engineering methods, such as finite differences or finite element analysis.

Furthermore, the integration of artificial intelligence and Deep Learning is accelerating this process, facilitating the prediction of macroscopic properties with an unprecedented level of control and precision. This hybrid approach reduces development times, minimises physical testing and optimises design from the earliest stages.

Quantum instrumentation and non-destructive measurements

During manufacturing processes, non-destructive measurements are a differentiating factor in terms of both cost and time. Detecting defects, monitoring critical parameters, and validating quality without damaging the component is essential in high value-added sectors.

Quantum technologies offer advanced solutions in this area. SQUID (Superconducting Quantum Interferometer Device) devices are capable of interacting with currents induced in carbon fibres and providing extremely accurate measurements of the material's condition, temperature, or the presence of small imperfections.

Likewise, light-based quantum interferometers can enable the study of the interior of the material with minimal interaction, facilitating more efficient quality controls and better optimised processes.

Quantum computing geared towards industrial processes

Quantum computing is beginning to emerge as a complementary line in the advanced digitisation of industrial processes. In the field of data analysis, various research centres are exploring quantum machine learning (QML) and Quantum Image Processing (QIP) algorithms which, in combination with classical and quantum non-destructive measurement techniques, could contribute in the future to optimising defect detection, signal classification and quality assurance in highly complex environments.

Although these capabilities are still in the development phase, their progressive integration with artificial intelligence tools and advanced monitoring systems opens up new perspectives for the efficient processing of the large volumes of data generated during the manufacture and operation of composite structures.

In the medium to long term, these technologies also offer the potential to address the efficient simulation of highly complex composite materials, especially in cases where classical computational methods have limitations. This evolution could reinforce multiscale simulation approaches, accelerating the design of new material architectures with optimised performance from the atomic scale to the final component.

A growing ecosystem

The applications described are part of a broader international strategy, driven by initiatives such as the European Quantum Flagship and various roadmaps on 2D materials and quantum technologies published in recent years. These strategic agendas highlight the central role that quantum materials will play in key industrial sectors during this decade.

Quantum energy and technologies should not be understood solely as a leap forward in computing, but as a cross-cutting transformation that directly impacts the engineering of advanced materials.

From highly sensitive embedded sensors to new multifunctional materials, multiscale simulations and extremely precise non-destructive inspection techniques, quantum technology is positioning itself as a strategic tool for the development of smarter, more efficient and safer structures.

In this context, integrating quantum capabilities into the design and manufacture of composite materials is not only a technological opportunity, but also a competitive advantage for those leading this transition.